Laboratory Testing

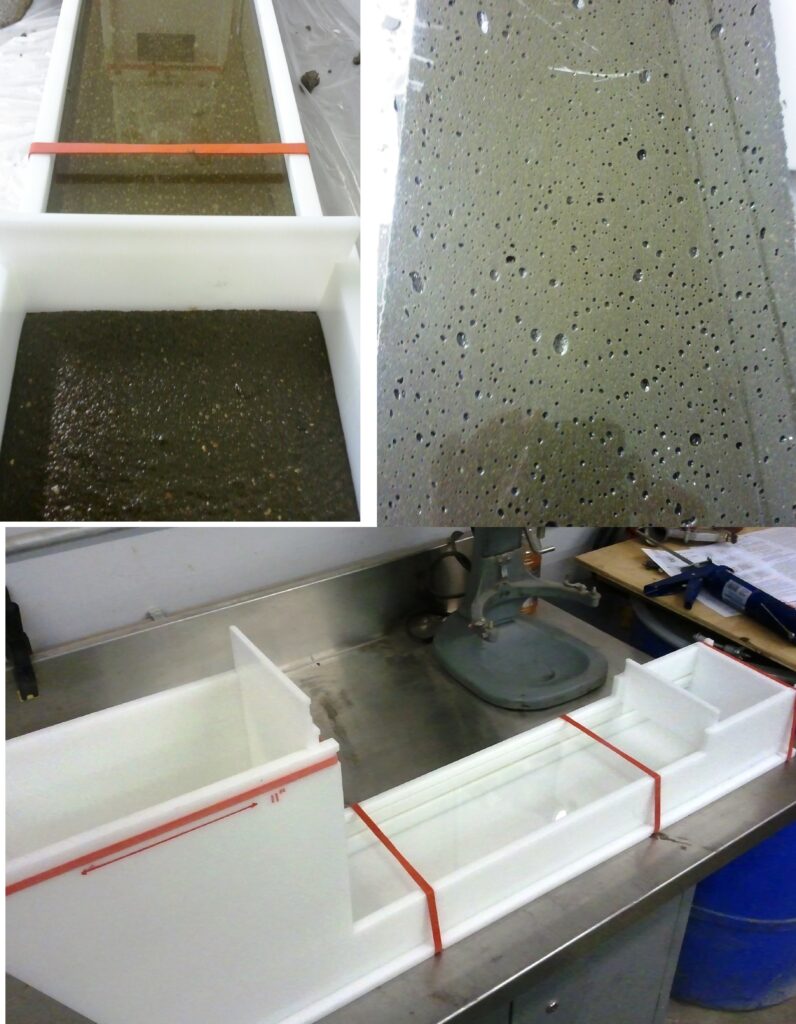

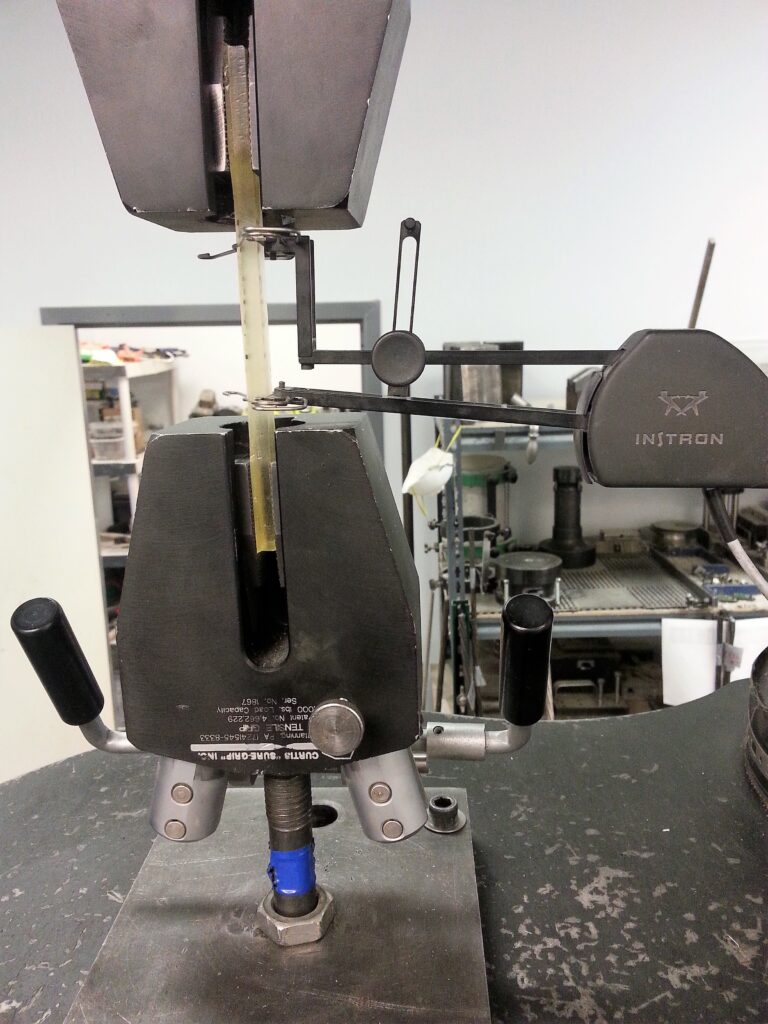

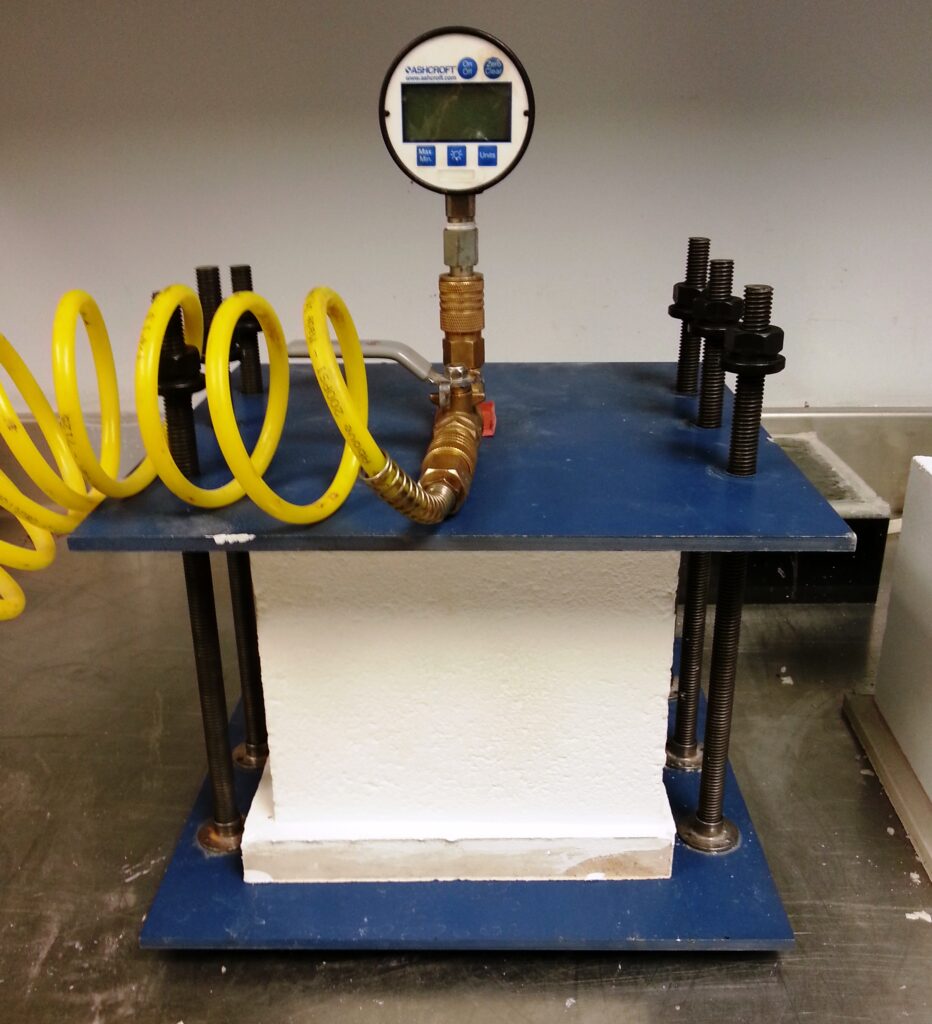

Our materials testing laboratory analyzes all classes of epoxies and coating for identification, chemical analysis and physical properties

We pride ourselves in the quality of our work and our capabilities in working with the epoxies and coatings industry. The objective material characterization is often to see if the epoxy and/or coating meets the required ASTM classification, DOT specification or Project specification. We provide our clients with the expertise, experience and knowledge to help with the most difficult project, as well as making them feel comfortable with our testing services.

Contact an expert for a complete list of tests we perform, or for questions concerning a particular test.

Test Methods

| ASTM C297 | Flatwise Tensile Strength of Sandwich Construction |

| ASTM C307 | Tensile Strength of Chemical – Resistant Mortars, Grouts, and Monolithic Surfacing, Chemical Resistant, Grout, Monolithic Surfacing, Mortar, Tensile Strength |

| ASTM C531 | Linear Shrinkage and Coefficient of Thermal Expansion of Chemical-Resistant Mortars, Grouts, Monolithic Surfacing, and Polymer Concretes |

| ASTM C579 | Compressive Strength of Chemical – Resistant Mortars, Grout, Monolithic Surfacing, and Polymer Concretes |

| ASTM C580 | Flexural Strength and Modulus of Elasticity of Chemical – Resistant Mortars, Grout, Monolithic Surfacing, and Polymer Concretes |

| ASTM C881 | Material Specifications for Epoxy Resins Base Bonding Resin |

| ASTM C884 | Thermal Compatibility Between Concrete and an Epoxy – Resin Overlay |

| ASTM C920 | Elastomeric Joint Sealants |

| ASTM D412 | Vulcanized Rubber and Thermoplastic Elastomers – Tension (Test Method A) |

| ASTM D570 | Water Absorption of Plastic |

| ASTM D624 | Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers |

| ASTM D638 | Tensile Properties of Plastic |

| ASTM D648 | Deflection Temperature of Plastic Under Flexural Load in the Edgewise Position |

| ASTM D695 | Compressive Properties of the Rigid Plastic |

| ASTM D790 | Flexural Properties of Unreinforced and Reinforced Plastic and Electrical Insulating Materials |

| ASTM D2196 | Rheological Properties of Non-Newtonian Materials by Rotational Viscometers |

| ASTM D2240 | Rubber Property – Durometer Hardness |

| ASTM D2247 | Testing Water Resistance of Coating in a 100% Relative Humidity |

| ASTM D2393 | Viscosity of Epoxy Resins and Related Components |

| ASTM D2471 | Gel Time and Peak Exothermic Temperature of Reacting Thermosetting Resins |

| ASTM D2556 | Apparent Viscosity of Adhesives Having Shear – Rate – Dependent Flow Properties Using Rotational Viscometer |

| ASTM D2566 | Linear Shrinkage of Cured Thermosetting Casting Resins During Cure |

| ASTM E1252 | General Techniques for Obtaining Infrared Spectral for Qualitative Analysis |

| ASTM E2485 | Freeze / Thaw Resistance of Exterior Insulation and Finish Systems (EIFS) and Water Resistive Barrier Coatings |

| ASTM R18 | Establishing and Implementing a Quality System for Construction Materials Testing Laboratories |

| ASTM AC212 | Acceptance Criteria for Water – Resistive Coatings Used as Water – Resistive Barriers over Exterior Sheathing |

| ISO/IEC 17025 | General Requirements for the Competence of Testing and Calibration of Laboratories |

| ASTM C510 | Test Method for Staining and Color Change of Single or Multicomponent Joint Sealants |

| ASTM C639 | Test Method for Rheological (Flow) Properties of Elastomeric Sealants |

| ASTM C661 | Test Method for Indentation Hardness of Elastomeric-Type Sealants by Means of a Durometer |

| ASTM C679 | Test Method for Tack-Free Time of Elastomeric Sealants |

| ASTM C719 | Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants Under Cyclic Movement (Hockman Cycle) |

| ASTM C793 | Test Method for Effects of Laboratory Accelerated Weathering on Elastomeric Joint Sealants |

| ASTM C794 | Test Method for Adhesion-in-Peel of Elastomeric Join tSealants |

| ASTM C1183 | Test Method for Extrusion Rate of Elastomeric Sealants |

| ASTM C1246 | Test Method for Effects of Heat Aging on Weight Loss, Cracking, and Chalking of Elastomeric Sealants After Cure |

| ASTM C1247 | Test Method for Durability of Sealants Exposed to Continuous Immersion in Liquids |