Engineering & Consulting

Non-Destructive Testing (NDT) refers to a wide group of techniques used to determine material properties without significantly damaging the material

Most NDT methods are based on sound or electromagnetic radiation principles. We typically use NDT to determine the as-built construction of structural and non-structural concrete and masonry. Our Primary NDT Techniques Include the following:

Half-Cell Potential Testing

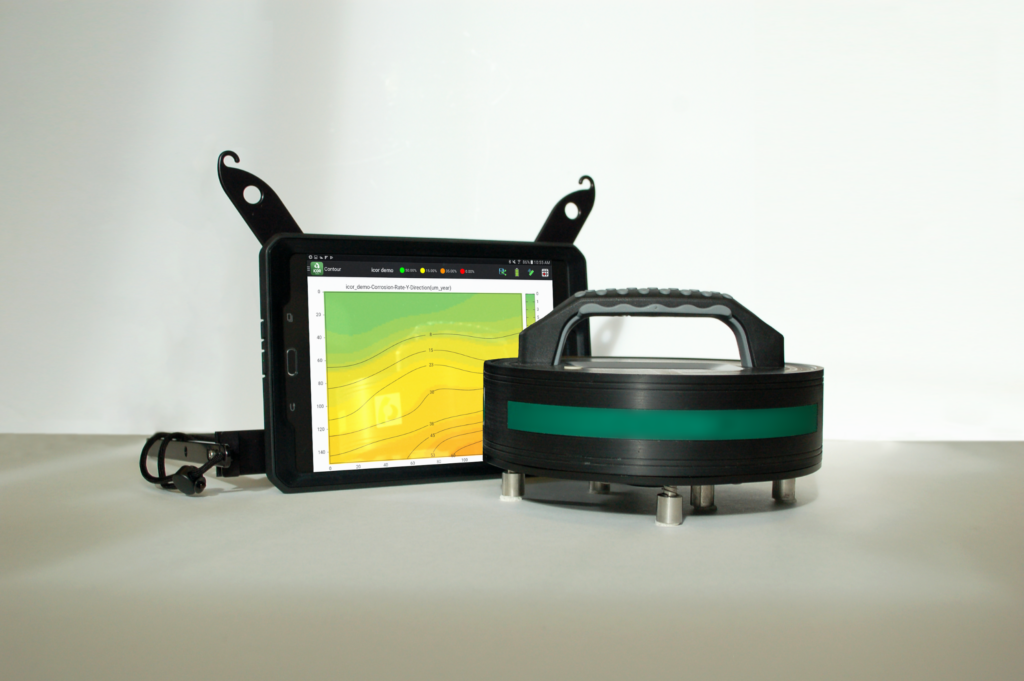

Half-cell potential testing is a method used for determining the corrosion activity of reinforcing steel in hardened concrete. The standard test procedure is presented in ASTM C 876, “Half-Cell Potentials for Uncoated Reinforcing Steel in Concrete.” The test method is based on the principal that during the electrochemical corrosion reaction an electric potential difference is generated in the reinforcing steel. The potential difference between the reinforcing steel (anode) and a copper sulfate half cell (cathode) gives an indication of the presence or absence of corrosion activity in uncoated reinforcing steel in concrete. Our experienced team of professional engineers utilizes the Giatec iCOR system. This device determines corrosion rate, half-cell potential, and in-situ electrical resistivity without exposing the embedded rebar. These measurements inform property managers, building engineers, and owners of the current and future potential for corrosion related cracking or spalling. Combining this testing with an overall condition assessment will provide invaluable life expectancy estimates for the structure.

Ground Penetrating Radar (GPR)

The ground penetrating radar (GPR) method uses electromagnetic energy, emitted at regular intervals by an antenna to map subsurface features and discrete objects. The electromagnetic pulses are reflected where changes in electrical properties (e.g. dielectric constants) occur. In the case of collecting GPR data on concrete structures, these reflections may occur due to the presence of rebar, cracking, voids, or the far side of the structure in question.

Impact Echo

Impact-echo testing is a special form of nondestructive stress wave testing of concrete. The usual method of nondestructive stress wave testing is the ultrasonic pulse velocity technique described in ASTM C597. ASTM has voted approval on a standard test procedure for the impact-echo technique but it has not yet been published. The test procedure utilizes stress waves which propagate through the concrete with the initiation and sensing of the stress wave being on the same surface of the concrete. The method can be used to determine the thickness of a concrete section, or if there are internal defects or cracks in the concrete. The uniformity of the concrete quality can be evaluated by this procedure.

Experience

- Ground Penetrating Radar (GPR)

- Impact Echo

- Corrosion Rate Assessment

- Half-cell Corrosion Potential Assessment

- Thermal Conductivity

- Moisture Testing

- Resistivity Testing

- Reinforcement Layout Verification

- Ultrasonic Pulse Velocity Testing

- Shear Wave Ultrasonic Tomography Testing

- Impulse Response Testing

- Holiday Testing

- Rebound Hammer Evaluation

- Concrete Permeability

- Coatings Thickness

- Surface Friction Testing

- Structural Monitoring

- Void Assessment

- Concrete Coring

- Bond Testing

Rebar Corrosion Non-Destructive Testing NDT

Corrosion of embedded reinforcing steel is the #1 cause of repairs, spalling, and failures in reinforced concrete structures. Until recently, rebar corrosion related distress could not be discovered until a crack or a spall was present. At this point, extensive costly repairs are necessary and potential life safety issues are present. Fortunately, non-destructive testing (NDT) technology exists, which allows for proactive discovery before a crack or spall occurs. This significantly reduces maintenance costs and can prevent the development of life safety risks and structural failures.

Ultrasonic Pulse Velocity

Determines the propagation speed of stress waves through a material, typically concrete or masonry. By measuring the time it takes for a wave to travel between two points, the technique can estimate the material’s quality, integrity, and potential defects. Pulse Velocity is effective in detecting voids, cracks, honeycombing, and assessing the uniformity and strength of structural elements.

Contact an expert for a complete list of tests we perform, or for questions concerning Non-Destructive Testing.