Petrography

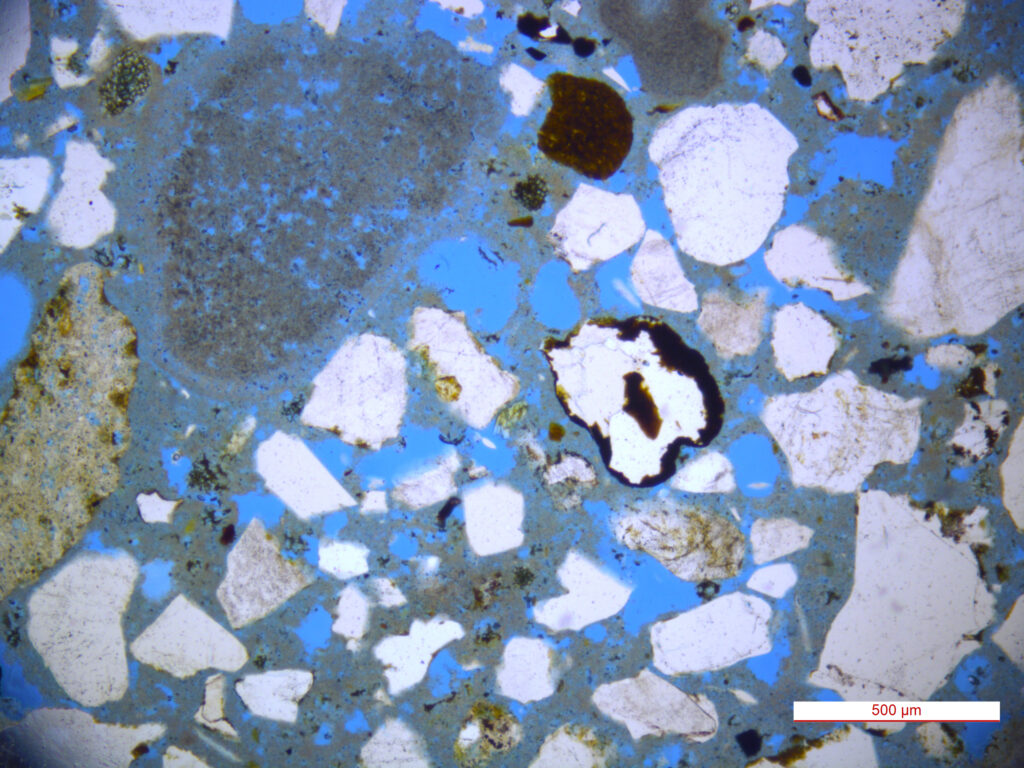

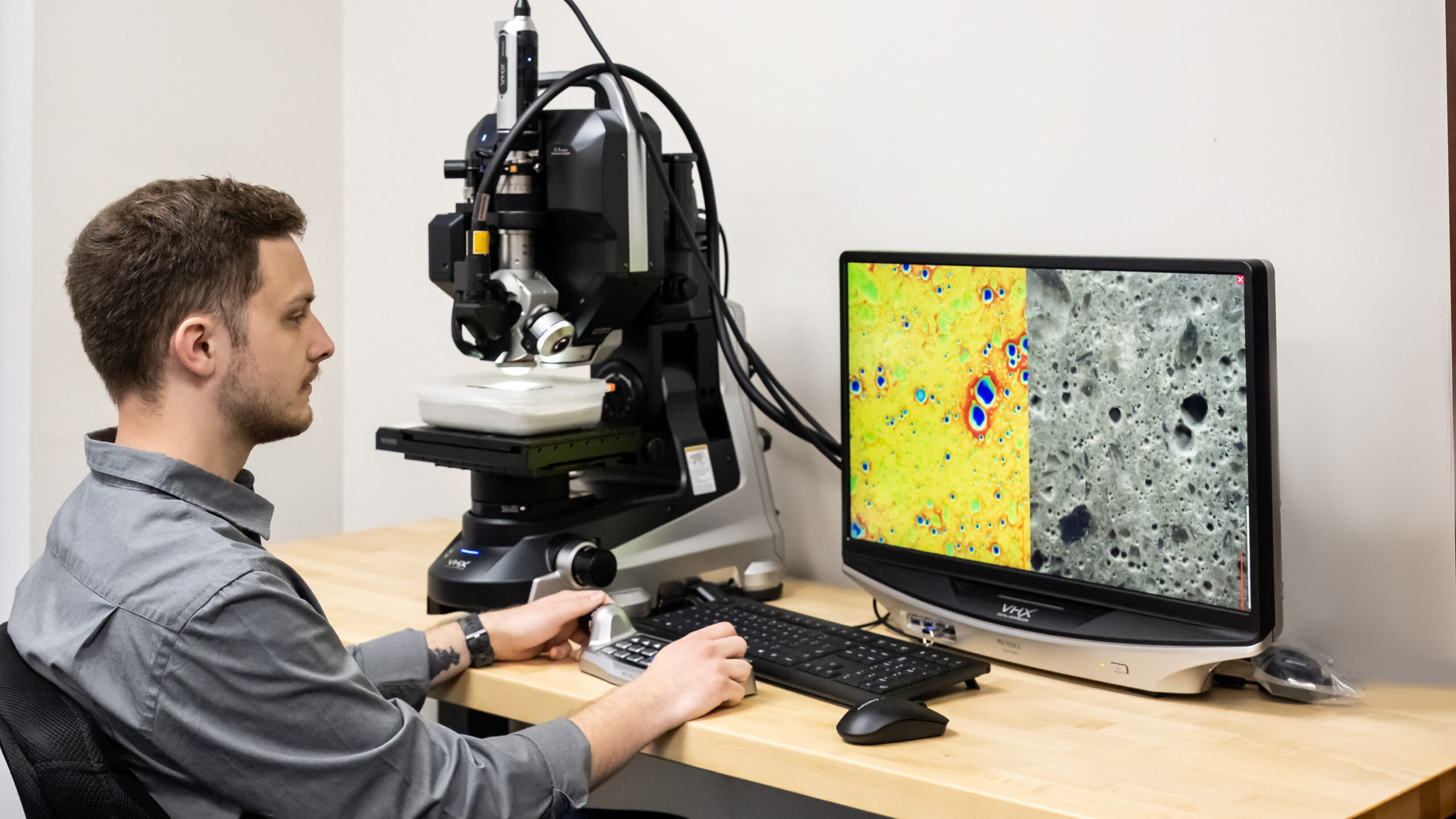

Petrographic evaluation is a forensic analysis technique used to examine building materials

Our laboratory evaluates the integrity of your materials by assessing quality, properties, deterioration causes, and current condition.

Petrography is most commonly applied to concrete ASTM C856 but can also be used to evaluate mortar ASTM C1324, grout, plaster, stucco, terrazzo, building stone, and raw materials such as cement and aggregate ASTM C295.

As a trusted leader, we offer you unparalleled quality assurance processes and our laboratory is ISO 17025, AASHTO R18 and Army Corps of Engineers accredited.

Our experienced team of professional petrographers, engineers, and geologists utilize advanced petrographic and chemical analysis equipment. Contact an expert for more information on our petrographic services.

Concrete

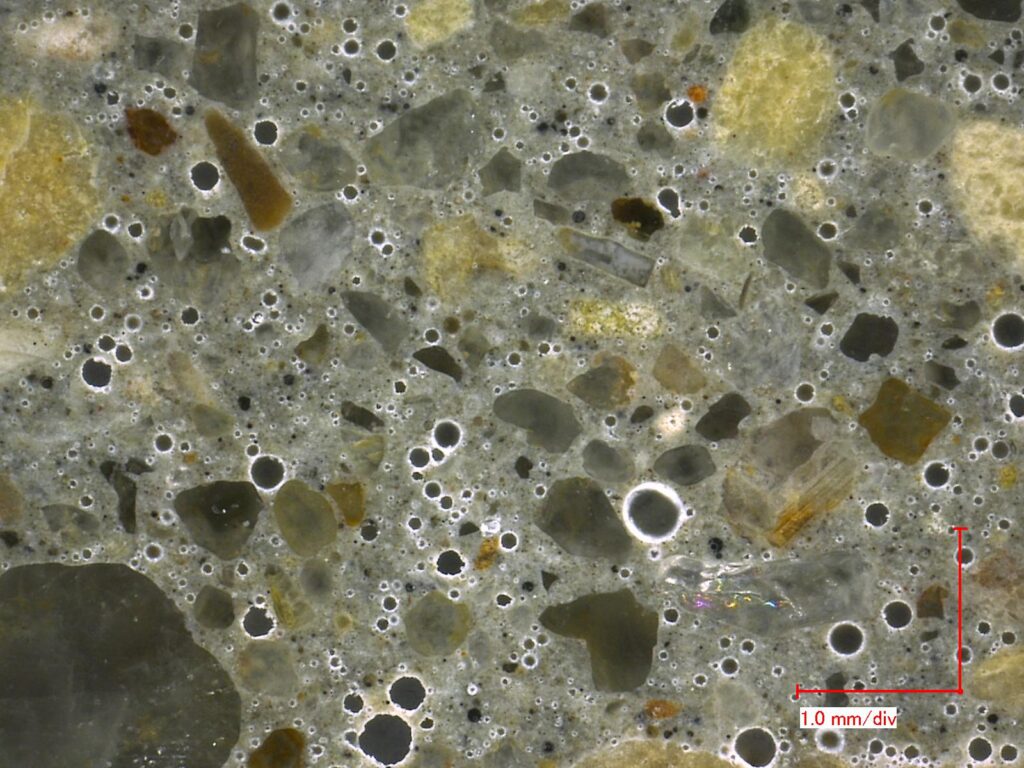

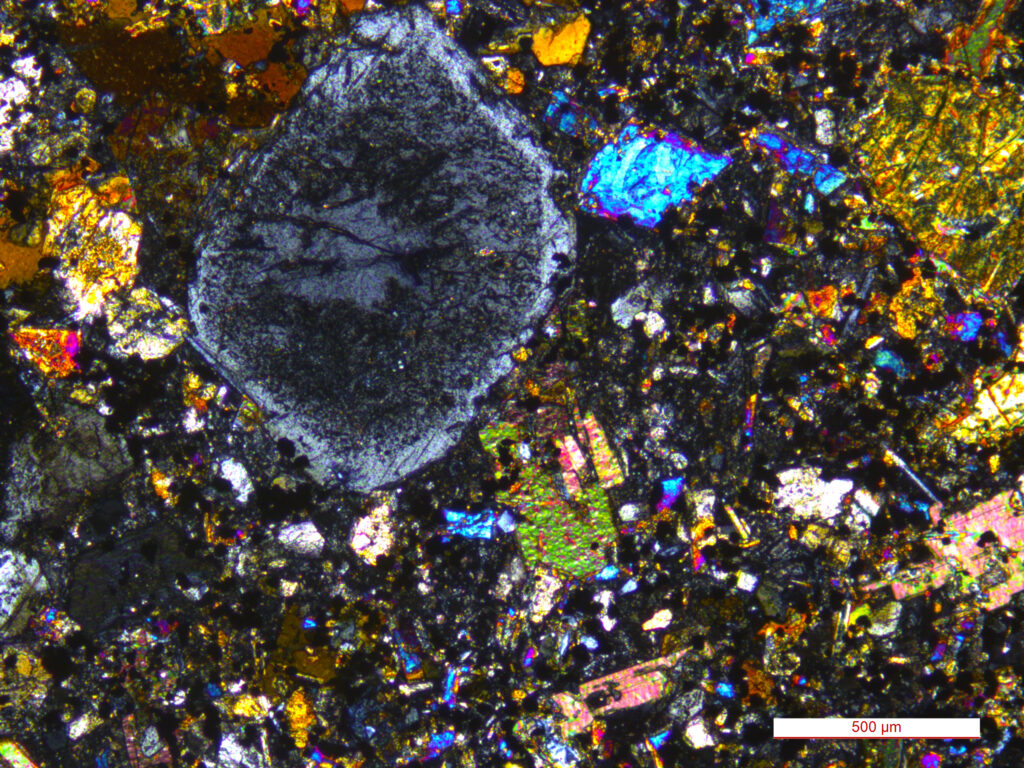

ASTM C856

- Water Content

- Air Content

- Chemical Attack

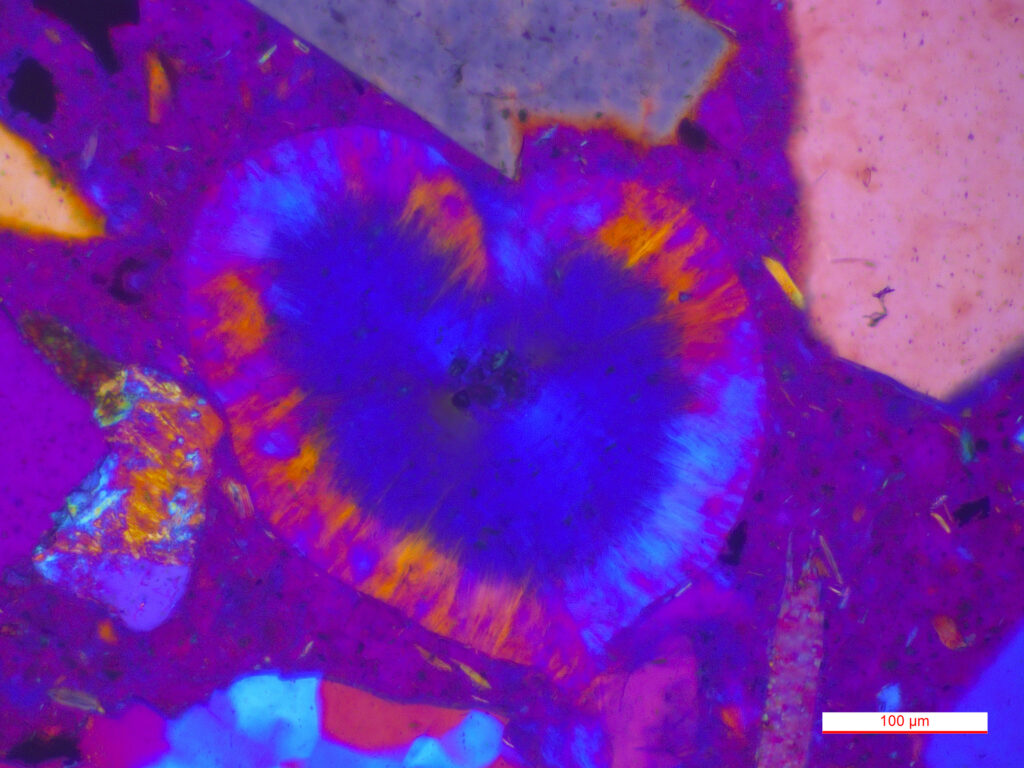

- Alkali Silica Reactions (ASR)

- Freeze Thaw Damage

- Paste Carbonation

- Corrosion of Rebar

- Fire Damage

- Cause of Cracking

- Sulfate Attack

- Improper Finishing

- Fly Ash, Slag, Silica Fume

- Aggregate Lithology

- Specification Compliance

- Service Life

Experience

- Spalling

- Cracking

- Coating Failure

- Moisture Vapor Issue

- Delamination

- Fire Damage

- Freeze Thaw Damage

- Contamination

- Low Strength Concrete

- Air Content

- Water Cement Ratio Estimation

Aggregates

ASTM C295

- Alkali-Silica Reactivity (ASR) Potential

- Alkali-Carbonate Reactivity (ACR) Potential

- Aggregate Lithology (Rock Type)

- Durability

- Staining Potential

- Rock Core Petrography

- Quarry Approvals

- Mica Content

- Quality

- Water Demand Effects

- Pyrrhotite Content

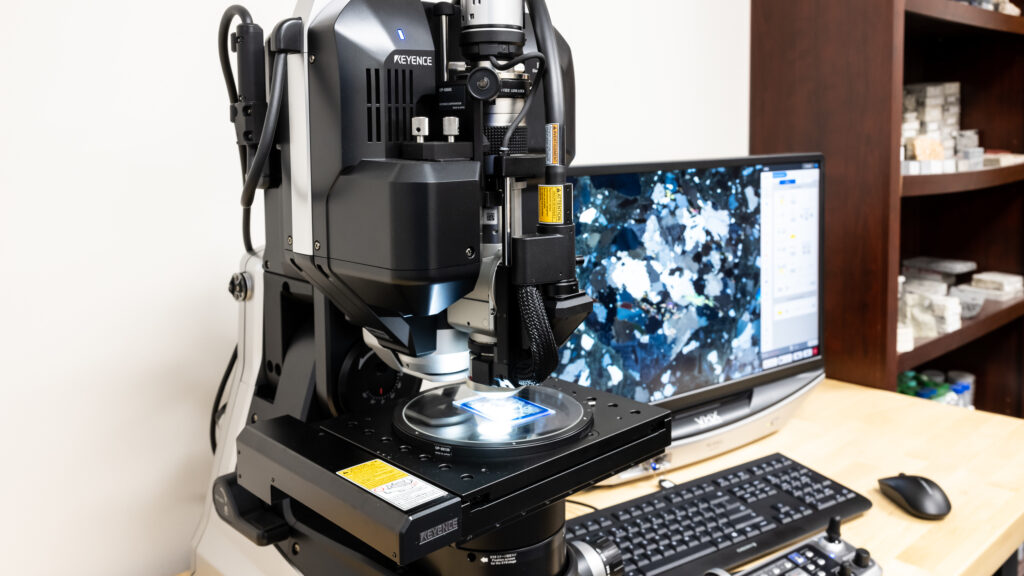

Laser-based Elemental Analyzer

Our laboratory uses an all-in-one solution for magnification observation and elemental analysis. Both can be done in real-time with no additional equipment or pre-processing requirements which is quite efficient. We simply observe and identify materials instantly and accurately.

Approaches:

- Helps identify minerals or particulate phases

- Generate chemical compositions

- Detects elements substituted in primary components (i.e. iron in sphalerite, nickel in pyrrhotite)

- Differentiate various components (i.e. gold/sulfosalt differentials)

Digital Microscope Features:

- Quick and reliable imaging, reporting and measurement all within the same system

- Magnification range of 20x – 2000x

- 20 times greater depth of field than conventional microscopes

- 2D & 3D measurement capabilities

- Live depth-up Z-scan

- Surface profiles

- Auto area measurements for particle counting

- Ring, coaxial, and transmitted light options

- Polarization capabilities for viewing thin sections

- Elemental and chemical analysis of samples with no sample prep necessary

Petrography can answer the following questions

- Why are my compressive strength values less than the design?

- How do I know the provided concrete matches the mix design?

- Was too much air entrainment added to the concrete?

- Is it time to remove and replace the existing concrete slab?

- Why do I have so much efflorescence on my concrete?

- Did the material quality contribute to the building collapse?

- What is the condition of the concrete in the old building?

- What is the probable future performance of my concrete?

- Why is my slab surface color blotchy?

- How much surface preparation is required?

- Why are there so many cracks in my slab?

- Why did the surface of the concrete flake off?

- What materials were used in the historic mortar?

- Can this aggregate be used in concrete?